Piping Design Services

How do you execute your projects?Most contractors when asked say, "We don't do design!", so let's talk about that! We have been in this business for almost 40 years some of us, so we can remember when that was mostly true. We delivered pipe and fittings to the job and spent the next couple of years installing the project. Well, it's not like that anymore, is it?

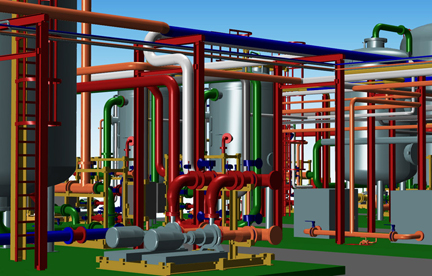

Now we are given, a much shorter amount of time, we all need to fabricate to get our jobs done on time, AND we are all involved in "Piping Design" to get this accomplished. Our project get planned, sketched, detailed, submitted and approved, all in the name of better project efficiency and project execution planning. That is what we are talking about when we are offering you "Piping Design Services". |

How does it work?Great question! We have found that you either know exactly how to manage this process OR you have absolutely no idea how to drive this process! Either way we can help you get your project completed on time and under budget!

Let's say you have a large mechanical room, and you want fabricate this as part of your project bid so you can be more competitive. Send us the drawings and we will give you a price to get you to spool level drawings at bid time. Once you get the project, you send us the needed project documentation, and we get started. We all hold a kick-off meeting discussing the team and assigning responsibilities, and then we get started on the mechanical room design. There are several levels of approval and verification, and when it is all done you get a 3D and 2D deliverable to give to your customer for approval so you can get it built in the fab shop and have your project ready to go in no time! |

Contractor Driven Team EffortWe don't try to take this job out of your capable hands, actually quite the contrary. It is our intent to be a value added part of you project team, and we will be providing you with just a piece of what you need to get accomplished to make this project a huge success!

In the "kick off meeting" we will assign responsibilities and discuss how this effort will be the most successful, but at the end of the day, this is a contractor driven process. On some of our larger more successful projects, we periodic meetings talking about progress, changes, approvals and deliverables scheduling. This is the only way the project stays on track and on schedule. All site coordination needs to belong to the contractor or contractors rep because we don't participate in on-site services to help you keep your costs down. Ultimately, we are part of your team for the duration of the project as is required and we will help you get your project done the right way the first time! |

Drawings and DeliverablesYou are hiring us so we can help you get your project completed in a professional manner and also to provide you with value and more money in your pocket! This is understood!

Our design effort begins with contract documents depending on the type of project. We will them start to create the 3D drawing that the piping and equipment layout will be based on. Our first step is to agree on the equipment room layout of equipment, devices, and ceiling heights. We would also agree on any obstructions that may impede our layout. The next step is to agree with all the piping routing and the exact piping main heights, service requirements of the equipment, housekeeping pad heights, and all else to get the piping in place. Finally, all the devices, valves, control valves, flow controls, thermometers and such are all in place to make sure the design is complete! |

What do we need to get started?It not too difficult, we need everything! We need the contract drawings, all the approved submittals, the temperature control drawings/submittal, the device and valve cut sheets, and any on-pipe or in-pipe items that must be part of this project. We could also use some pictures, if available or applicable, so we can see what you are seeing.

We will then go through everything and let you know if we need anything additional. If there are any changes along the way, we will need to know about those too. Remember, it is our intent to give you a solution that work correctly the first time! Armed with the most up to date information, we can do exactly that! |

We are all falling short in the design department!Have you noticed there is a gap between the project's stated intent, and what the drawings are actually showing? Of course you have! For the last 10 years, maybe more, contractors have picked up the lion share of the design risk and responsibility in the name of Design Build or even worse, plan and spec projects that have incomplete IFC drawings.

Most of the time lately, we are all working from incomplete drawings for the bid, and the IFC drawings fall completely short of giving you a buildable solution. Most mechanical rooms any more are not even drawn. They show the lines going into the room with a reference to the P&ID! What? Let us help you here, don't throw your project supervision a bad situation, give this problem to us and let us complete the picture with a 2D/3D completed set of detailed drawings! |