Pharmaceutical and Sanitary Industrial Piping

Estimating "Clean" and "Ultra Clean" SystemsDo you do sanitary or pharmaceutical work? This is really a quite specialized field, and finding a Total Mechanical Estimating System that includes is pretty rare. Many of the systems out there claim to give you the parts and pieces but in reality when you try to use them, they are hard to understand and even more difficult to complete the bid.

There are lots of model numbers that most of us do not know, and there are many intricacies of this work that if you don't or haven't done this work you just don't know. We try to make it easier to understand, and try to sort through some of the complexities of the system for you. Give us a try and see why we are different! |

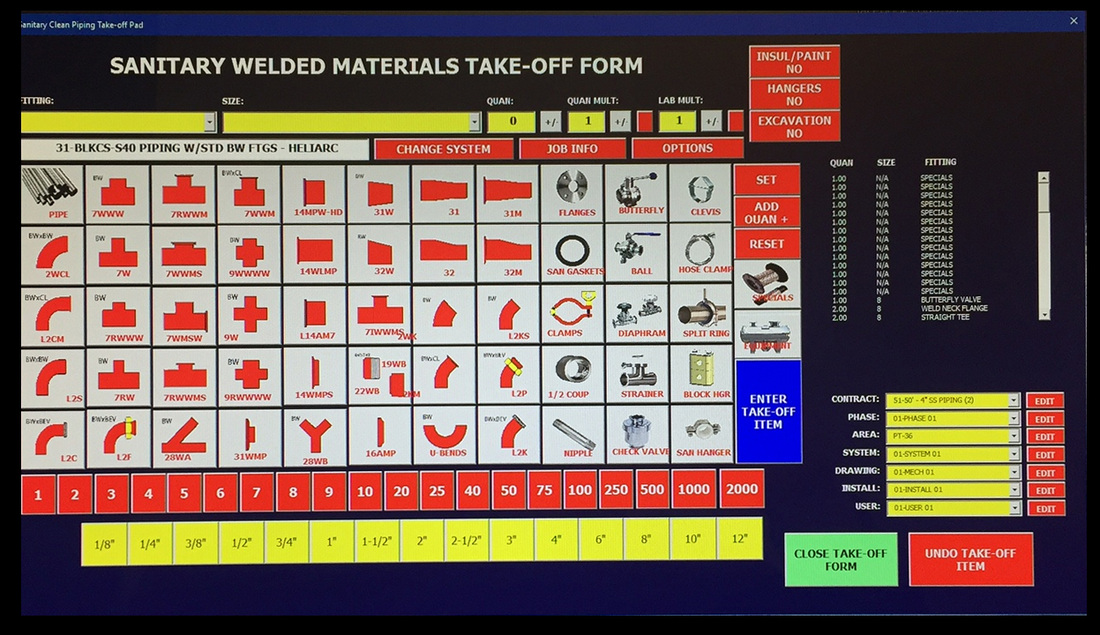

Clean Piping Take-offWhether it is SS 316 butt weld schedule 5 pipe being TIG welded, or a SS 304 schedule 10 line being TIG welded with an argon purge for a food line, or a SS 316 Pharmaceutical line being welded with an orbital, we have you covered!

You need to have the tools you need to bid this work effectively. Not only do the parts need to be in the database but the equipment and the expendables need to be accounted for as well. If for some reason, you are using something often that we do not have, we will make every effort to get into the database for you so you job is easier. We have both clamp systems and butt weld systems for you to use, as well as sanitary piping and pharmaceutical grade fittings and pipe too. If you need it we have it so you can do your job Our system will add expendables, welding rod costs, Argon costs, and will even give you the weight of the system with and without water! Finally, you can add insulation as you go, choose to acknowledge that cost if you want, you can add couplings as you go and hanger costs can be calculated and counted as you go too. |

Specialties and EquipmentEspecially in the Industrial Estimating arena for these types of projects, it is pretty much a given that you will be doing at least part of the project under what would be termed a shutdown.

So how do you quantify your inefficiencies? What could happen to your project? You may have to add manpower that has not been on the project. You may have to work overtime not needed on the remainder of the job. You will have inefficiencies and added safety costs that were not on your original estimate. If you have to get people from out of town to work this shutdown, you might have to add perdiem costs too. In most estimating systems, you don't get an opportunity to address these costs as easily as they are addressed with ours. In our system, you can set the shutdown schedule, the number of men and the duration, and then you are able to address all these costs separately with our shutdown breakout. This one item could cost you thousands of dollars if you do not get it right. It is much more complicated than just adding the intended overtime differential and moving on. Let us help you get it right every time! |

FabricationFor the last 30 years, the mechanical contracting industry has been actively pushing prefabrication to help save on labor and be considerably more effective and competitive. This entails pipe detailing and allotting a portion of the project to the prefabrication effort.

Our system addresses all of these things within our program so you don't have to do it. You certainly are the one making all the decisions and driving the choices in the program but in the final recap the splits are there and can be manipulated. Another useful tool that we have to offer is the fabrication can be split into spools. If you are quoting a spooled project, you can take-off per spool and get a report that quantifies each spool by labor hours, fabrication costs, general conditions, and final totals for each. It is critical to do fabrication to be successful in this business. You do not need to have the biggest and the best fabrication facility, but the pre-planning and efforts to streamline your installation and minimize your "on site" presence need to be a part of the equation in a manner that saves you money. This is the number that we encourage with our system at bid time! |

Clean and Ultra Clean SystemsIf you have done "Clean" work, then you know it is expensive and for the most part a fairly unproductive process. This needs to be understood and covered in the project bid. We help you cover things like NDE services, Argon usage for welding and purging, welding equipment, boroscope purchase or rental, QC services, fabrication requirements and costs, and the list goes on.

A bid like this is involved and can become one that gets simpler if you have a system that helps like ours does. Be sure you trust your bidding software to people who understand your challenges and the dynamics of getting a job like this done! |